Image 1 of 5

Image 1 of 5

Image 2 of 5

Image 2 of 5

Image 3 of 5

Image 3 of 5

Image 4 of 5

Image 4 of 5

Image 5 of 5

Image 5 of 5

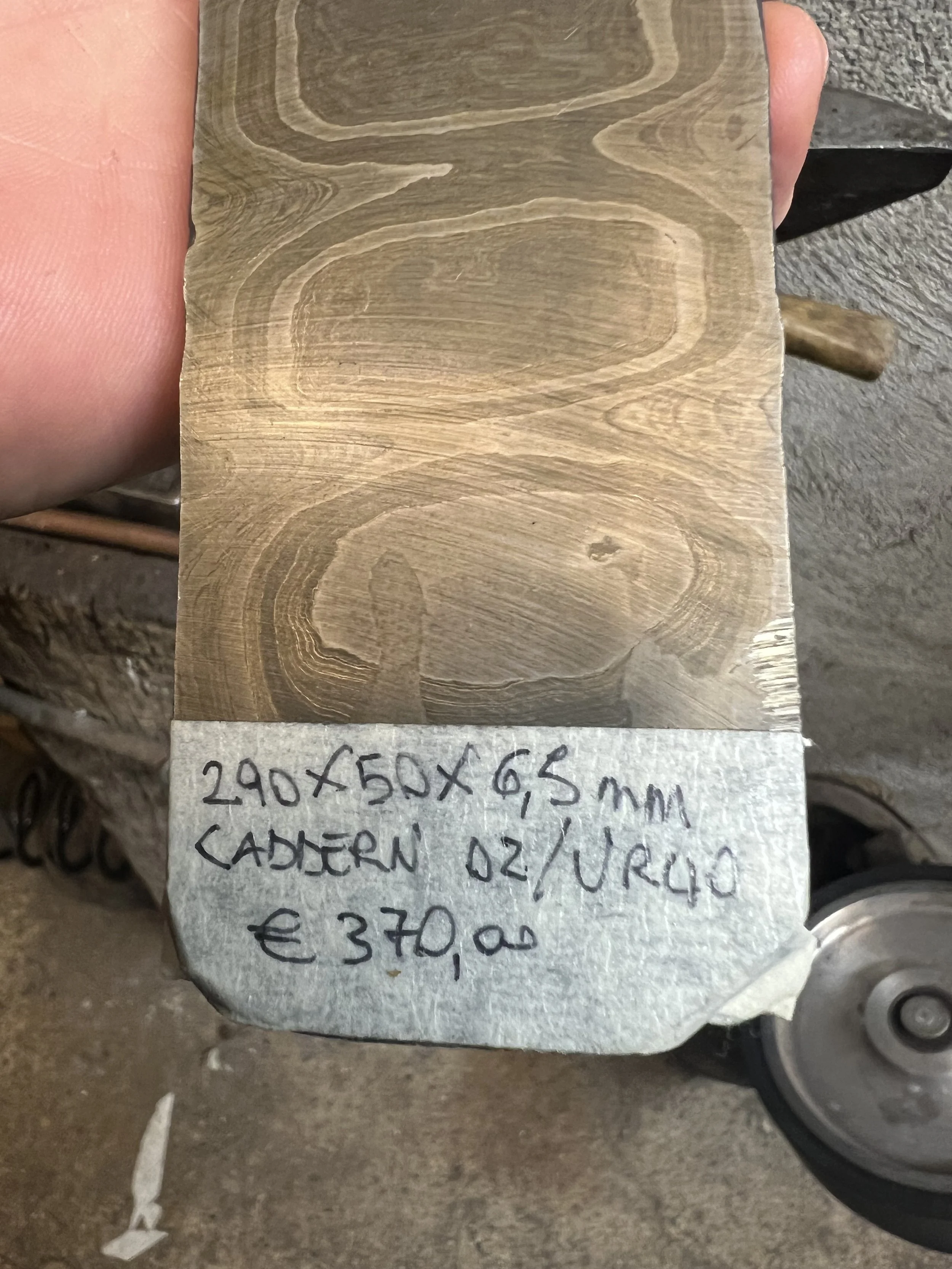

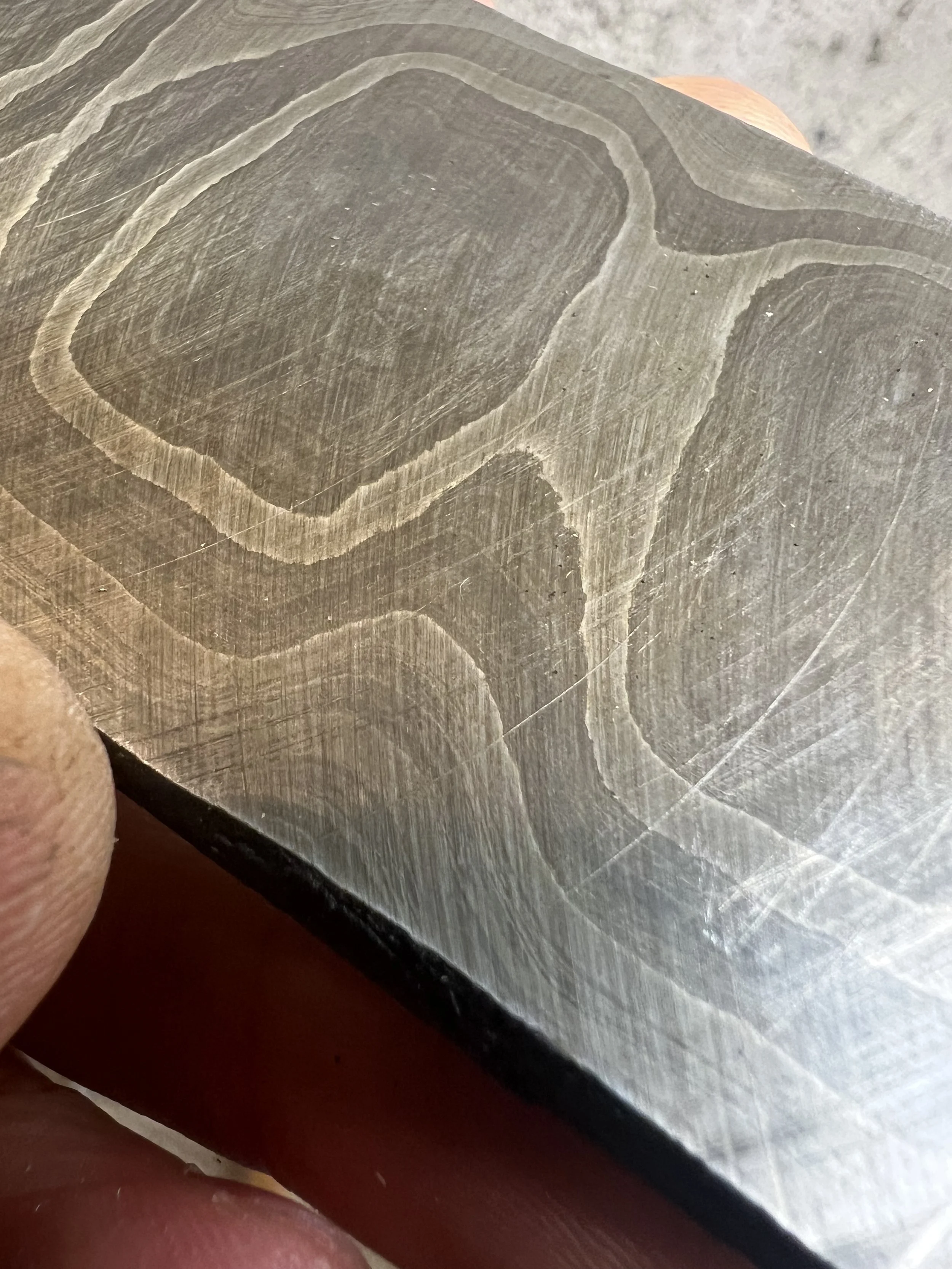

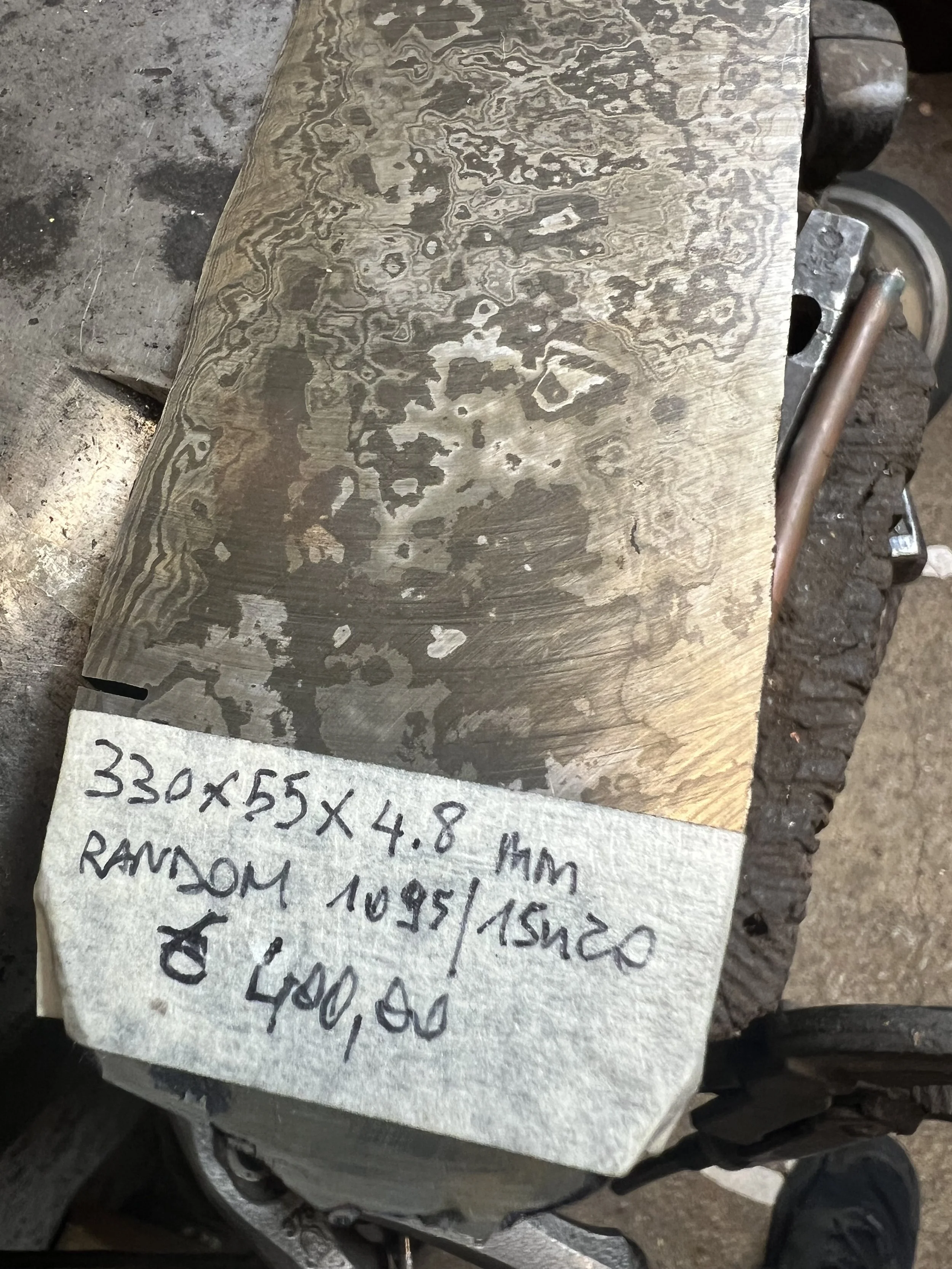

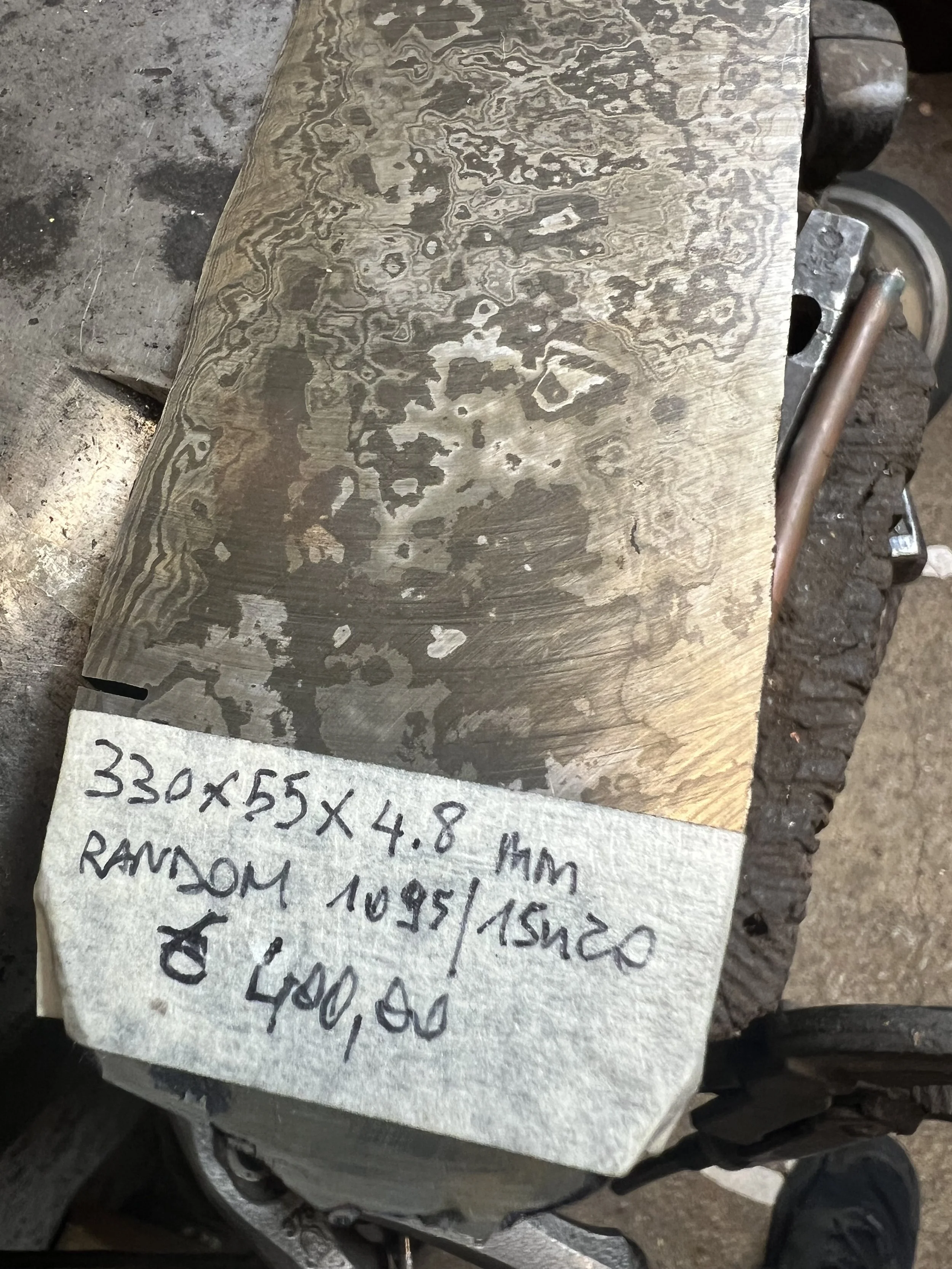

Random Damascus billet

Forged billet: 1095 / 15N20 carbon steel — 330 mm x 55 mm — thickness 4.8 mm

This billet is an excellent choice for knife making. It combines 1095 high-carbon steel and 15N20 nickel steel in the classic pattern-welded (Damascus-style) pairing, giving you a reliable balance of hardness, edge retention, and visual contrast. Key features:

Steel combination: 1095 offers excellent toughness and hardenability, producing a sharp, long-lasting edge. 15N20 contributes toughness and a bright, nickel-rich contrast that highlights the pattern after etching.

Dimensions: 330 mm length × 55 mm width × 4.8 mm thickness — a very useful size for a wide range of blade types: chef’s knives, utility knives, bushcraft blades, and compact larger folders. The thickness (4.8 mm) is substantial enough for robust blades while still allowing fullering, profiling, and thinning to final geometry.

Workability: The billet has been annealed, reducing hardness and internal stresses so it’s ready for cutting, profiling, grinding, and forging without the difficulty of hardened stock. Annealing simplifies shaping and prevents cracking during heavy work.

Surface condition: Surfaces are flattened, giving you a true, even starting face for marking, layout, and precise grinding. Flattened faces save setup time on the belt grinder or planer and help ensure consistent thickness across the blade.

Pattern potential: The 1095/15N20 pairing produces attractive high-contrast patterns after etch. With this billet’s dimensions and thickness, you can employ twists, ladder patterns, or simple stack-and-weld approaches to achieve a striking final appearance.

Heat treatment: After shaping, you can heat treat the 1095/15N20 to typical 1095 hardness ranges (often 57–62 HRC depending on tempering) to maximize edge retention. Because the billet is annealed, you’ll get predictable results from your hardening/quenching cycle.

Practical considerations: At 4.8 mm, anticipate some stock removal during profiling and tapering—plan grinding allowances accordingly. If you intend very thin kitchen blades, more thinning is required; for mid-weight to heavy-duty knives, this thickness is ideal.

Overall, this annealed, flattened 1095/15N20 billet at 330 × 55 × 4.8 mm gives a smith a ready, versatile blank for producing durable, attractive knives with excellent edge performance and clear Damascus contrast. If you like, I can suggest heat-treat parameters and finishing steps tailored to the blade type you plan to make.

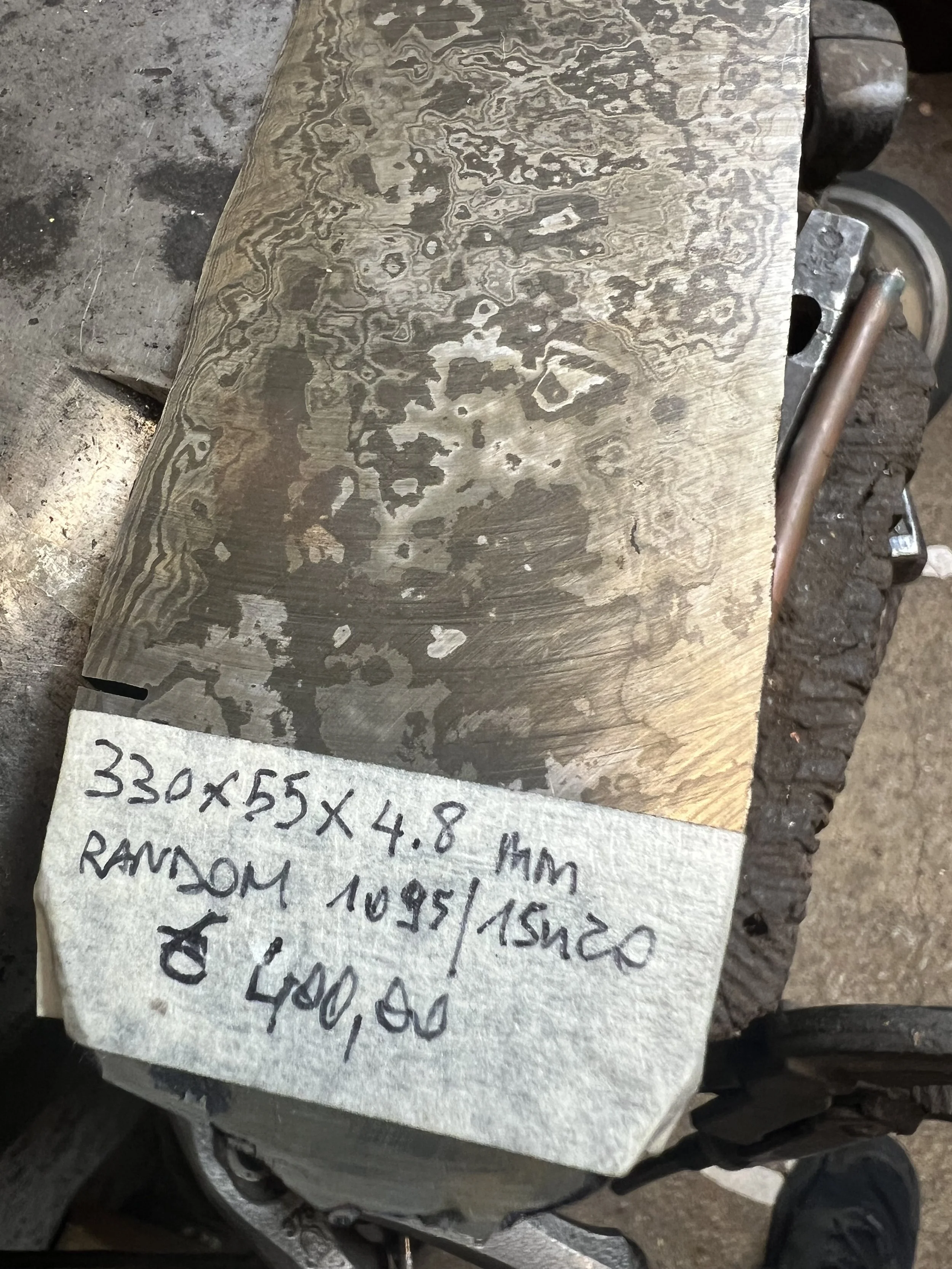

Forged billet: 1095 / 15N20 carbon steel — 330 mm x 55 mm — thickness 4.8 mm

This billet is an excellent choice for knife making. It combines 1095 high-carbon steel and 15N20 nickel steel in the classic pattern-welded (Damascus-style) pairing, giving you a reliable balance of hardness, edge retention, and visual contrast. Key features:

Steel combination: 1095 offers excellent toughness and hardenability, producing a sharp, long-lasting edge. 15N20 contributes toughness and a bright, nickel-rich contrast that highlights the pattern after etching.

Dimensions: 330 mm length × 55 mm width × 4.8 mm thickness — a very useful size for a wide range of blade types: chef’s knives, utility knives, bushcraft blades, and compact larger folders. The thickness (4.8 mm) is substantial enough for robust blades while still allowing fullering, profiling, and thinning to final geometry.

Workability: The billet has been annealed, reducing hardness and internal stresses so it’s ready for cutting, profiling, grinding, and forging without the difficulty of hardened stock. Annealing simplifies shaping and prevents cracking during heavy work.

Surface condition: Surfaces are flattened, giving you a true, even starting face for marking, layout, and precise grinding. Flattened faces save setup time on the belt grinder or planer and help ensure consistent thickness across the blade.

Pattern potential: The 1095/15N20 pairing produces attractive high-contrast patterns after etch. With this billet’s dimensions and thickness, you can employ twists, ladder patterns, or simple stack-and-weld approaches to achieve a striking final appearance.

Heat treatment: After shaping, you can heat treat the 1095/15N20 to typical 1095 hardness ranges (often 57–62 HRC depending on tempering) to maximize edge retention. Because the billet is annealed, you’ll get predictable results from your hardening/quenching cycle.

Practical considerations: At 4.8 mm, anticipate some stock removal during profiling and tapering—plan grinding allowances accordingly. If you intend very thin kitchen blades, more thinning is required; for mid-weight to heavy-duty knives, this thickness is ideal.

Overall, this annealed, flattened 1095/15N20 billet at 330 × 55 × 4.8 mm gives a smith a ready, versatile blank for producing durable, attractive knives with excellent edge performance and clear Damascus contrast. If you like, I can suggest heat-treat parameters and finishing steps tailored to the blade type you plan to make.