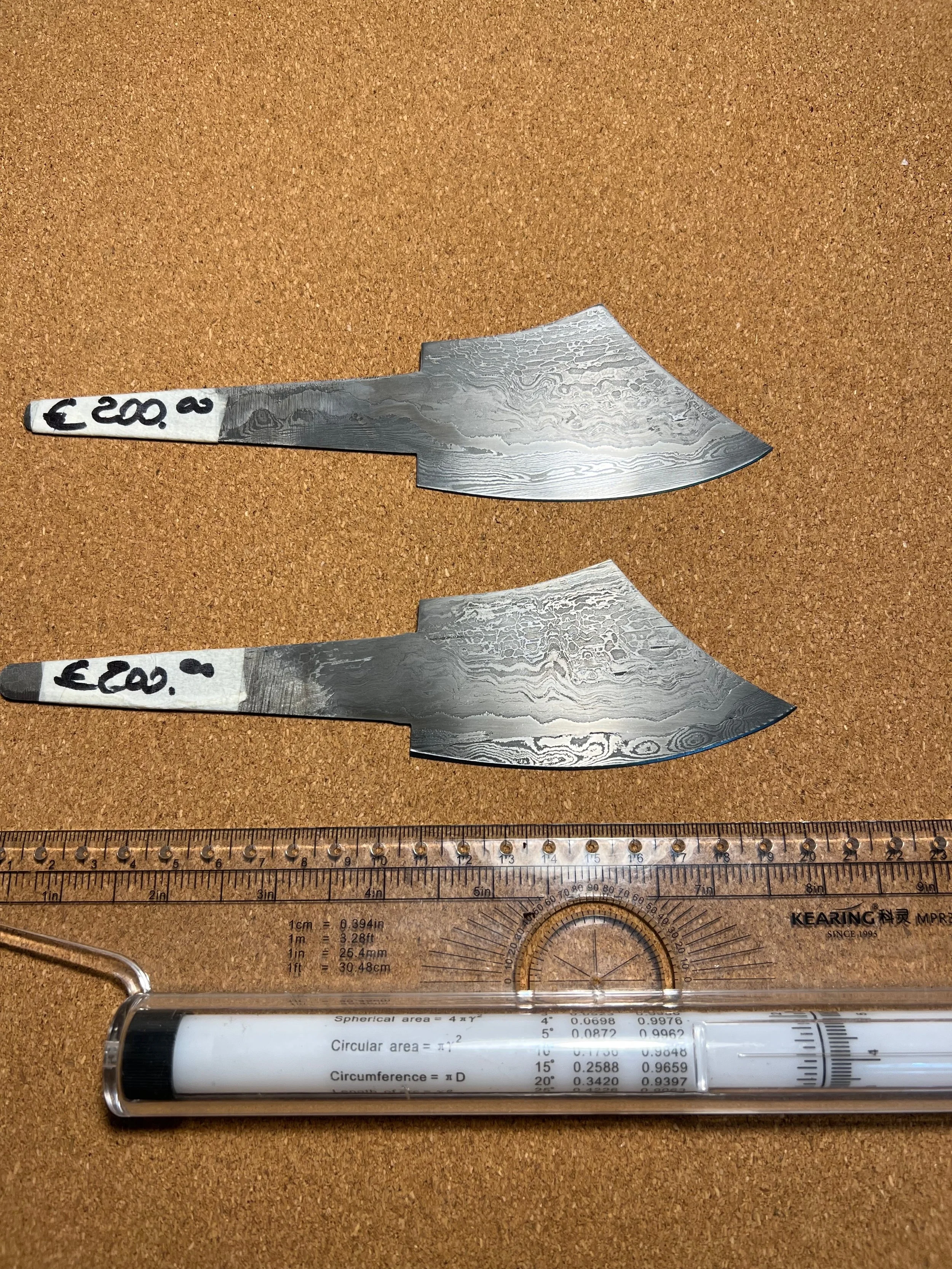

Image 1 of 4

Image 1 of 4

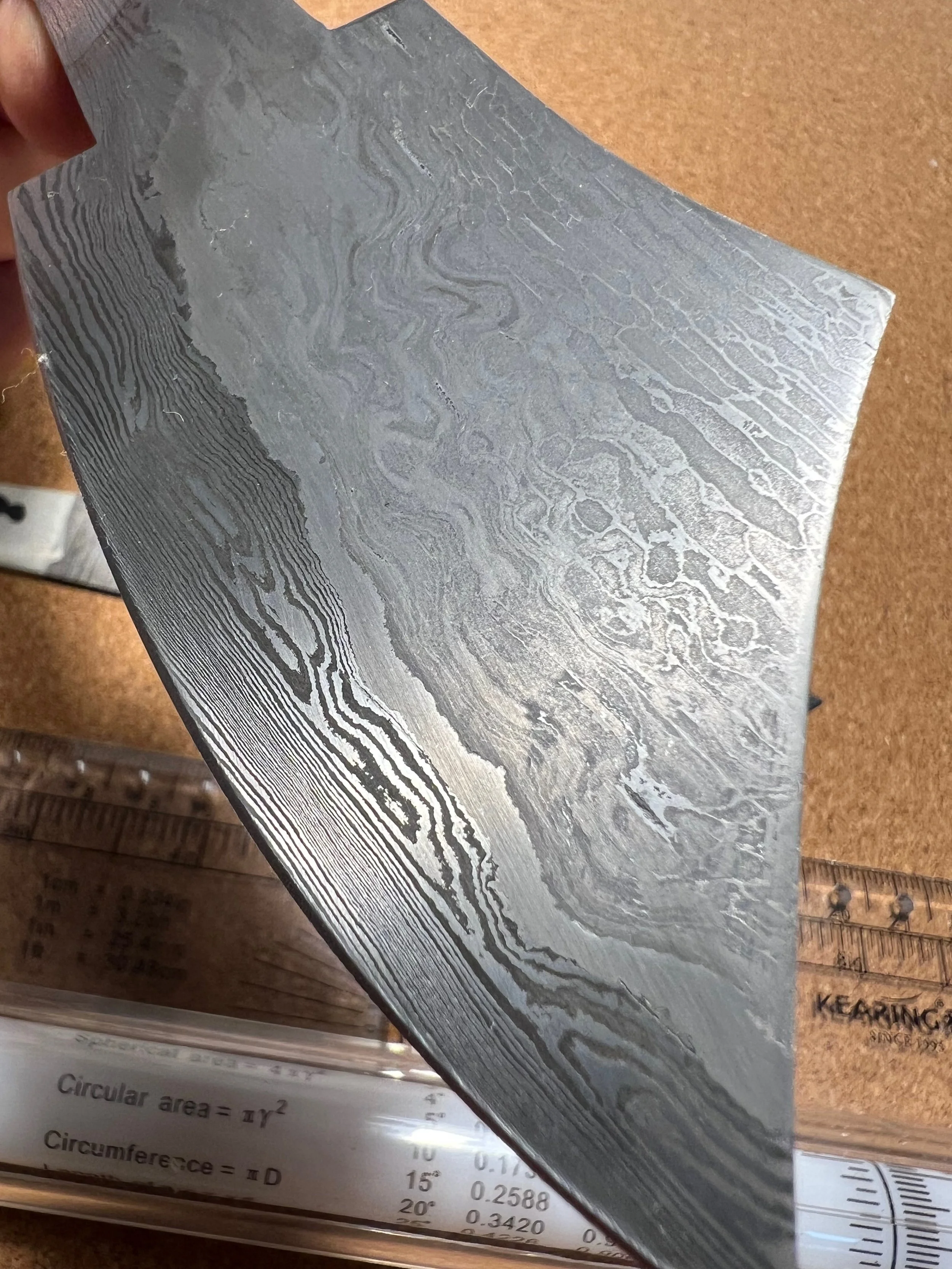

Image 2 of 4

Image 2 of 4

Image 3 of 4

Image 3 of 4

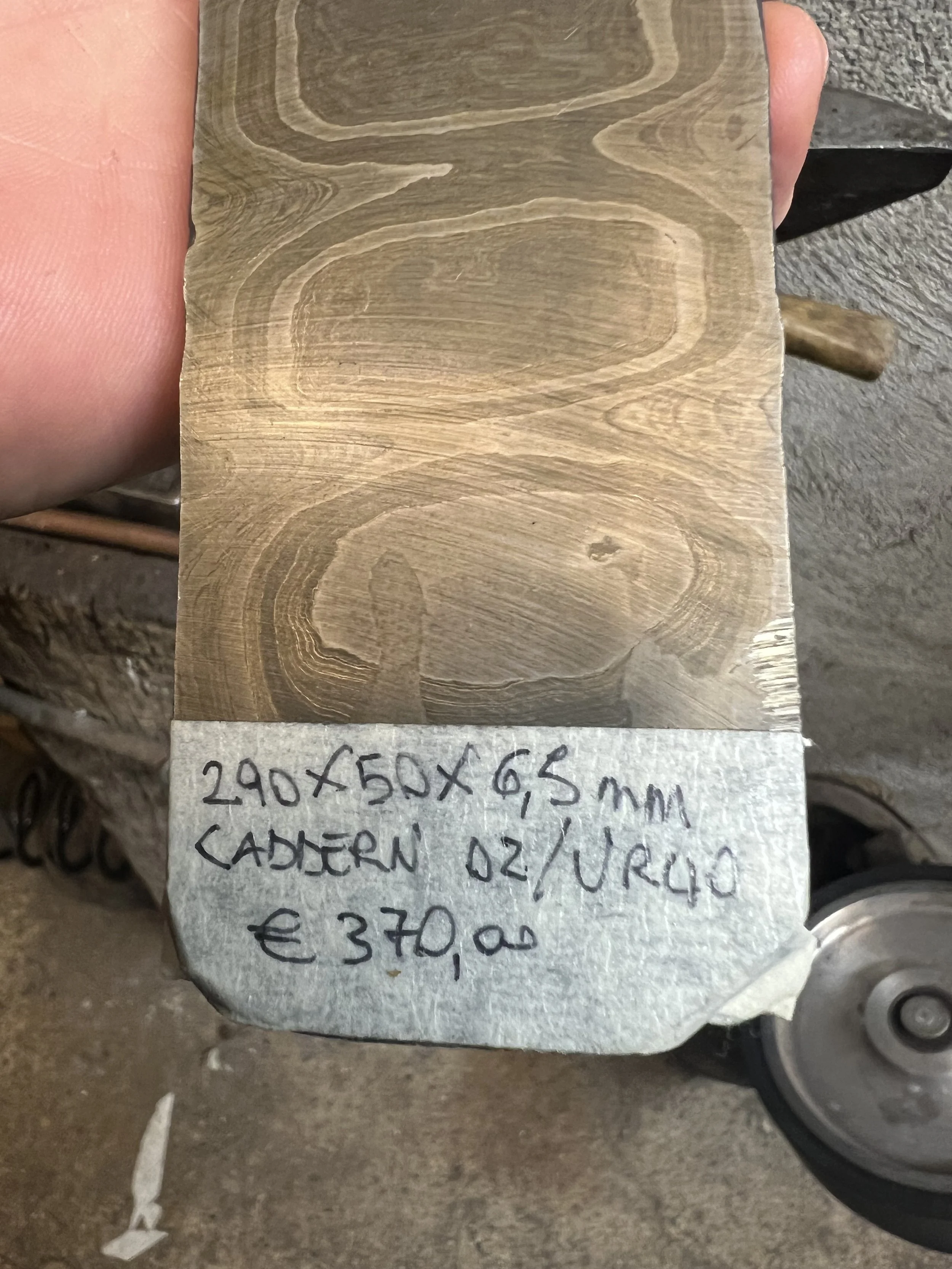

Image 4 of 4

Image 4 of 4

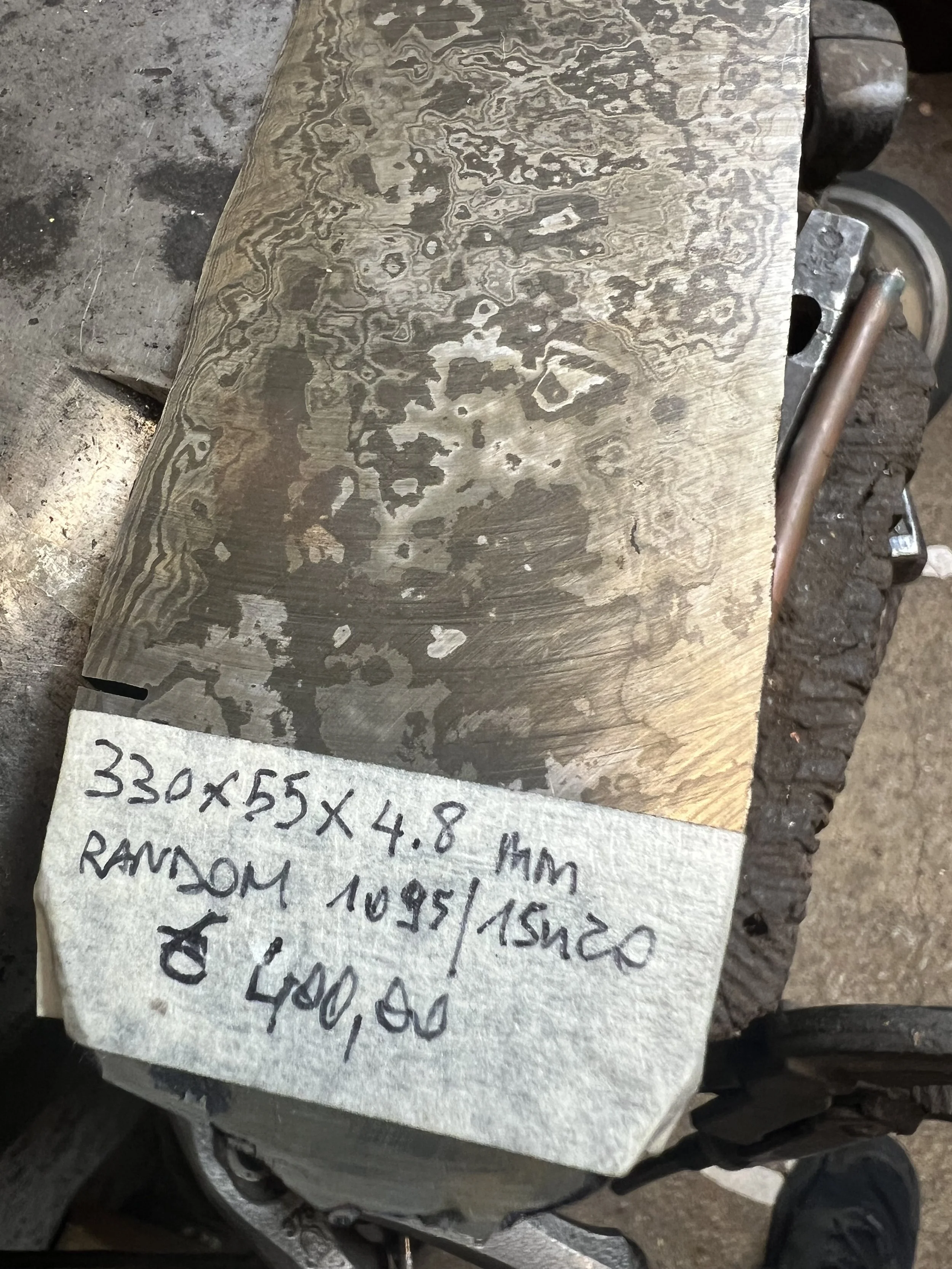

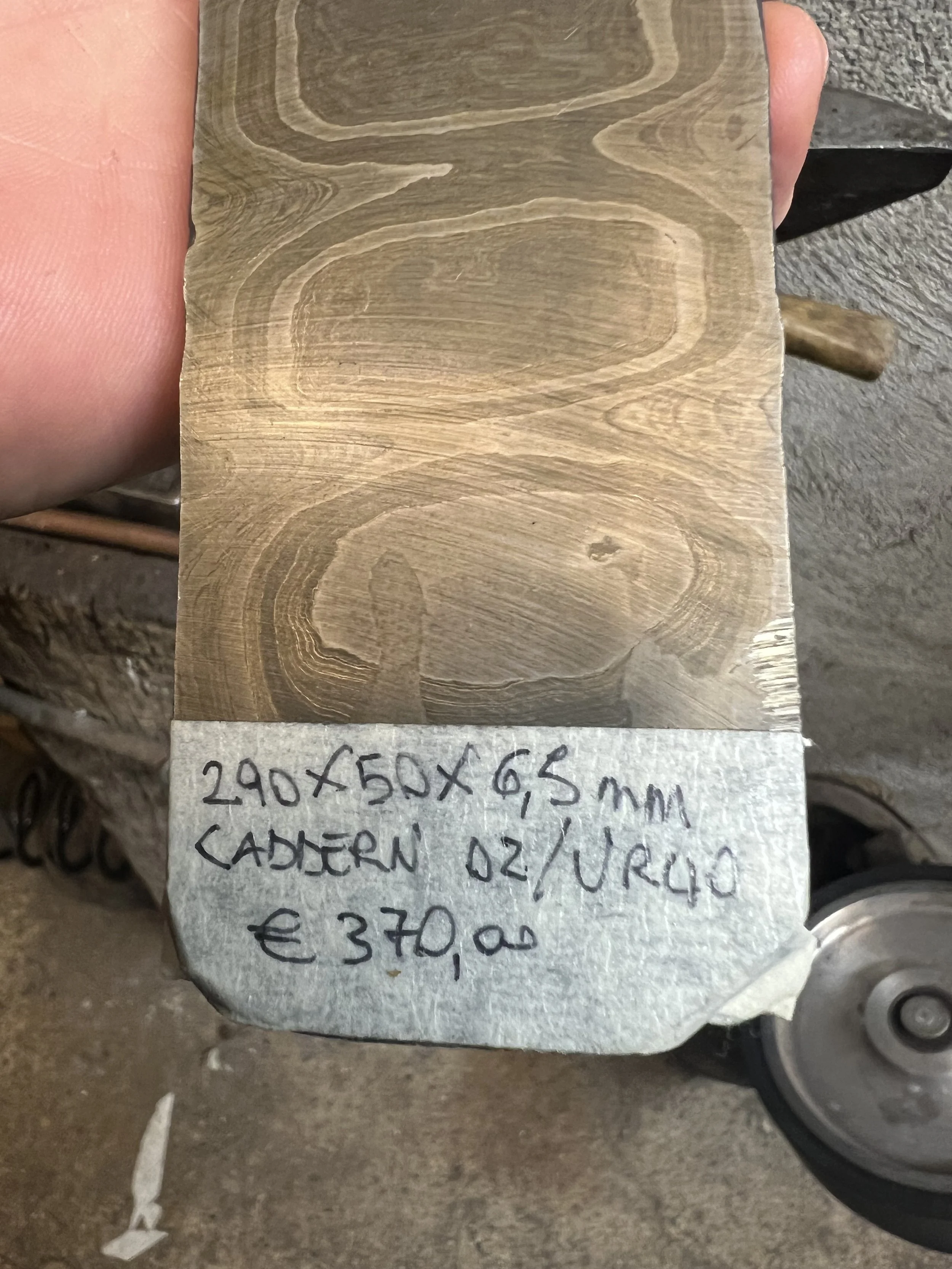

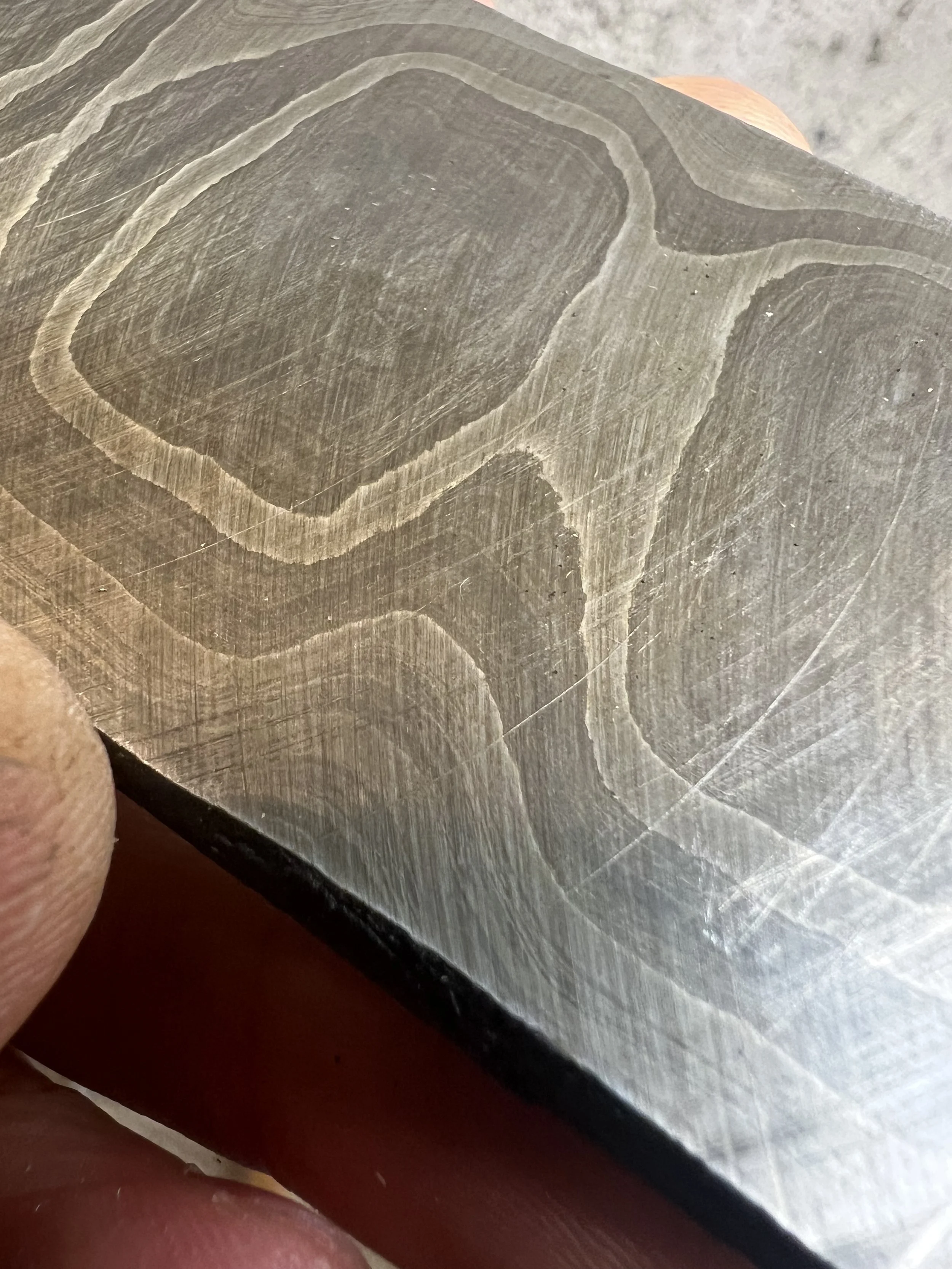

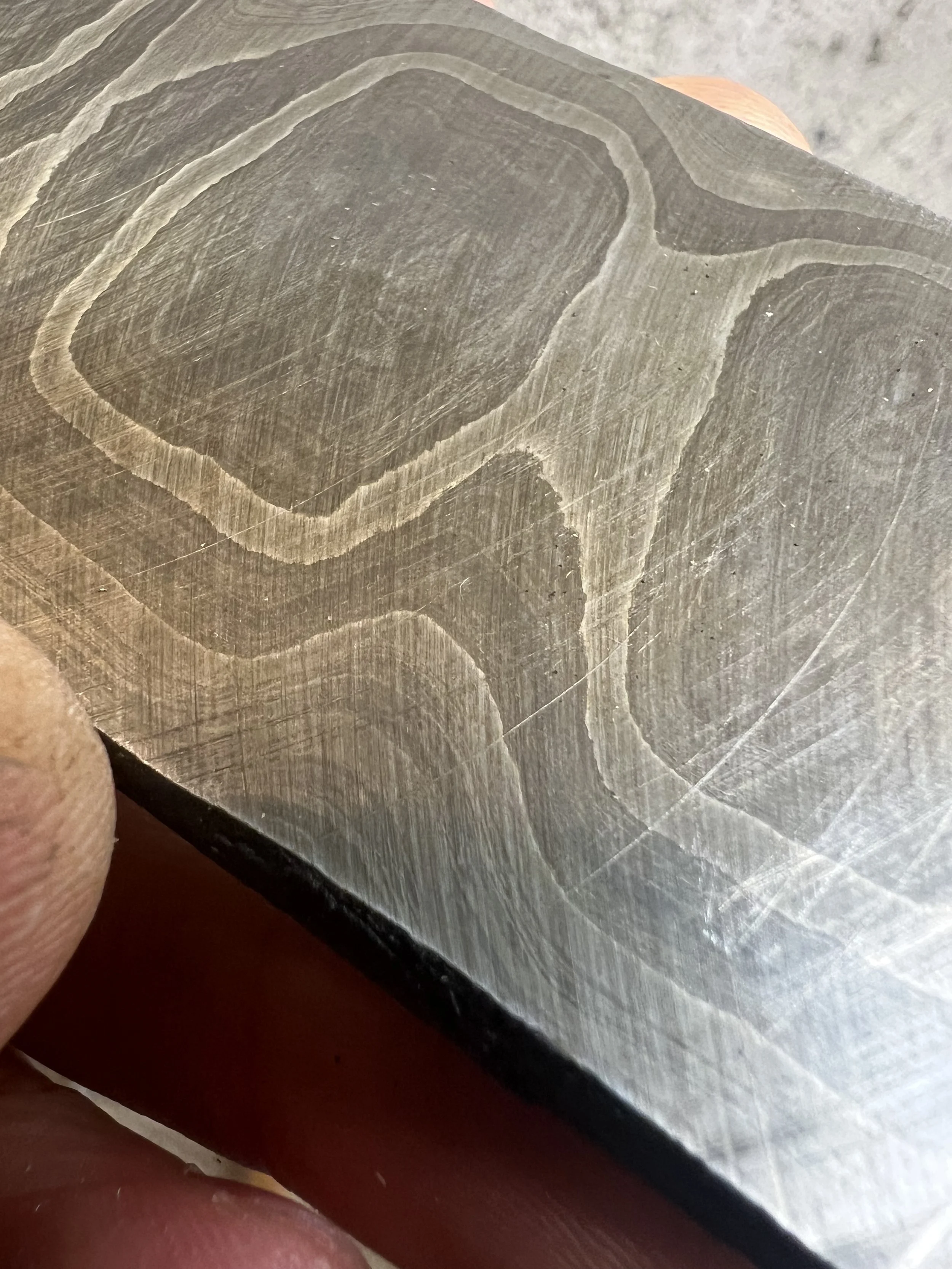

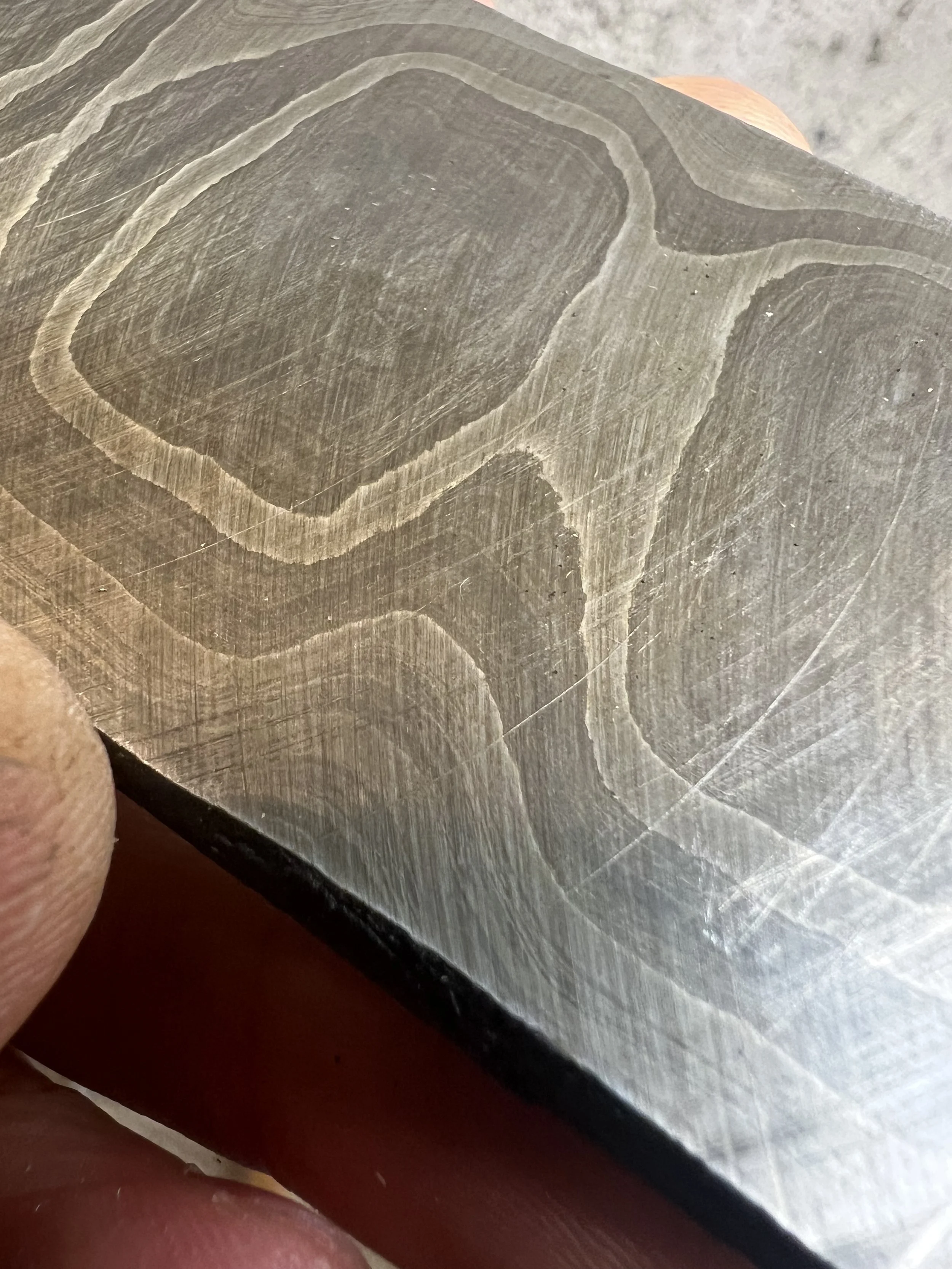

Ladddern pattern Damascus billet

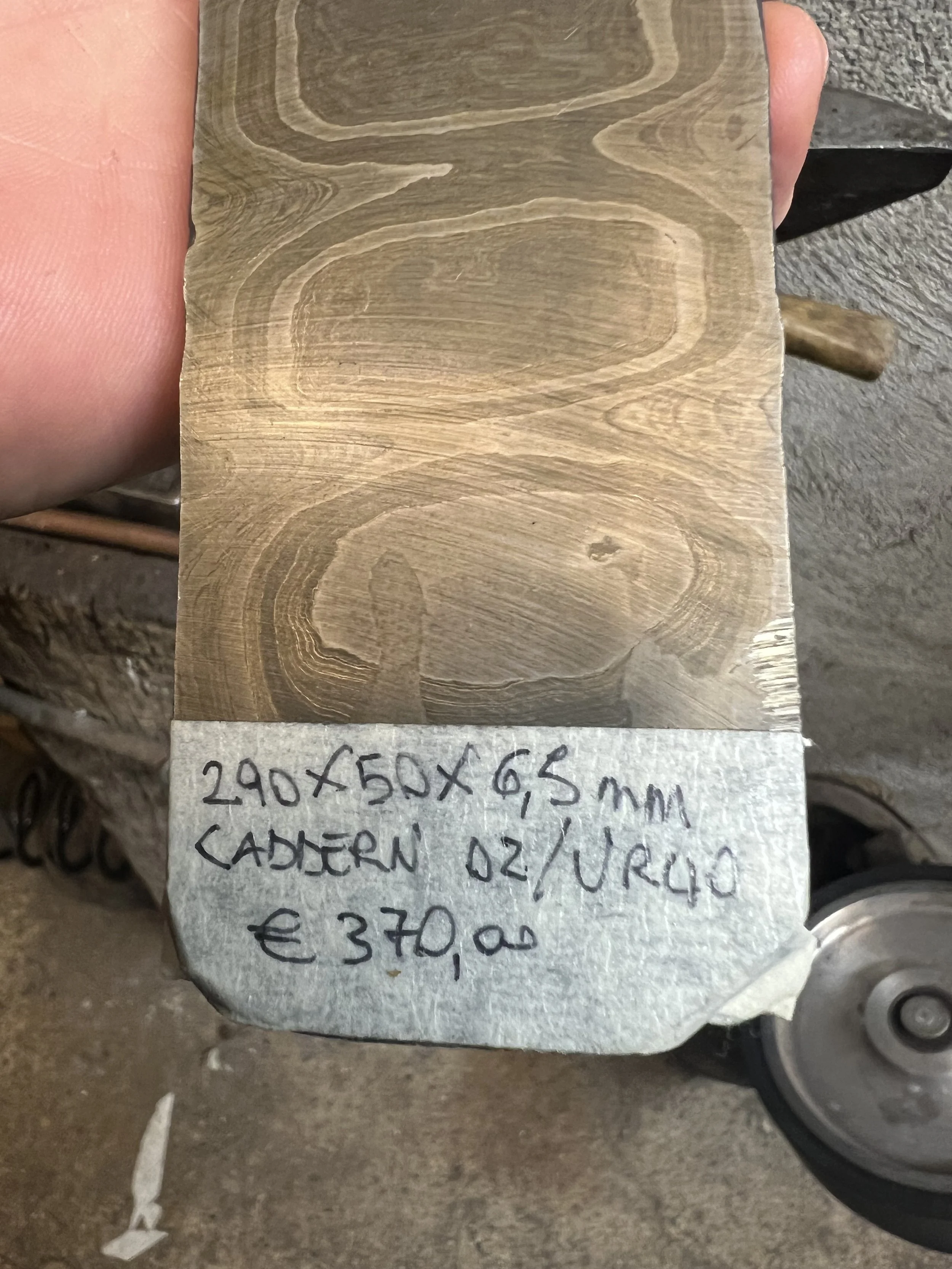

Ladders Pattern Damascus Billet — 290 × 50 × 6.5 mm

Every piece of Damascus steel I offer is forged by my own hands. From the initial stack and weld to the final shaping and etch, I control each step of the process to ensure the blade’s integrity, pattern, and performance. That means:

I select and prepare the steels myself, tailor the layer count and pattern to the intended use, and perform the forge-welds personally.

All pattern work—twists, cuts, and manipulations that create the Damascus figure—is executed by me at the forge.

Heat treatment, grinding, and hand-finishing are done in my workshop so I can guarantee balance, edge geometry, and a clean, consistent finish.

Etching and any final surface work are done by me to reveal the pattern exactly as intended.

When you buy a Damascus blade from FRANCESCATO BLADESMITH, you’re getting a knife born in my forge, crafted with hands-on attention, experience, and pride.

Handcrafted billet in a striking ladders pattern, ideal for custom knife-making. Layers of 1.2842 and 1.2767 high‑carbon steels have been forged, folded, and manipulated to produce a clear, tight ladders motif that reveals strong vertical rungs and well-defined rails when etched.

Specifications

Dimensions: 290 mm (length) × 50 mm (width) × 6.5 mm (thickness)

Steels: 1.2842 + 1.2767 (high carbon combination for excellent contrast and edge potential)

Pattern: Ladders — consistent, visually appealing, and well-suited to long blades or handles with visible patterning

Condition: Annealed for ease of cutting, grinding, and shaping; surfaces flattened for accurate stock removal and reliable measurements

Effect: Good contrast between steels, pronounced ladder rungs with controlled scale — excellent for both subtle and bold etched finishes

Why this billet works for knives

Blade geometry: 290 mm length and 50 mm width give ample stock for full‑size kitchen, hunting, or tactical blades; thickness (6.5 mm) provides good material for profile grinding and beveling while keeping plenty of material for heat treatment.

Steel pairing: 1.2842 and 1.2767 offer responsive hardenability and a clean etched contrast that highlights the ladders pattern after heat treat and etch.

Prep quality: Annealed and flattened surfaces save time during fabrication — you can scribe, cut, and grind with predictable material behavior and accurate dimensions.

Fabrication notes

Heat treat: Follow recommended hardening practice for each steel blend; test a sample to dial in quench and temper for your desired hardness and toughness balance.

Grinding: Use coarser belts initially but protect the pattern with light, consistent passes to avoid excessive heat buildup that can alter surface appearance before final etch.

Etching: Ferric chloride or dilute hydrochloric + peroxide produce strong contrast; test etch times on a scrap to refine the final look.

This billet is ready for knifemakers who want a dependable, attractive ladders Damascus with clean prep work — high carbon content, good contrast, and a flattened, annealed condition that speeds up the build.

Ladders Pattern Damascus Billet — 290 × 50 × 6.5 mm

Every piece of Damascus steel I offer is forged by my own hands. From the initial stack and weld to the final shaping and etch, I control each step of the process to ensure the blade’s integrity, pattern, and performance. That means:

I select and prepare the steels myself, tailor the layer count and pattern to the intended use, and perform the forge-welds personally.

All pattern work—twists, cuts, and manipulations that create the Damascus figure—is executed by me at the forge.

Heat treatment, grinding, and hand-finishing are done in my workshop so I can guarantee balance, edge geometry, and a clean, consistent finish.

Etching and any final surface work are done by me to reveal the pattern exactly as intended.

When you buy a Damascus blade from FRANCESCATO BLADESMITH, you’re getting a knife born in my forge, crafted with hands-on attention, experience, and pride.

Handcrafted billet in a striking ladders pattern, ideal for custom knife-making. Layers of 1.2842 and 1.2767 high‑carbon steels have been forged, folded, and manipulated to produce a clear, tight ladders motif that reveals strong vertical rungs and well-defined rails when etched.

Specifications

Dimensions: 290 mm (length) × 50 mm (width) × 6.5 mm (thickness)

Steels: 1.2842 + 1.2767 (high carbon combination for excellent contrast and edge potential)

Pattern: Ladders — consistent, visually appealing, and well-suited to long blades or handles with visible patterning

Condition: Annealed for ease of cutting, grinding, and shaping; surfaces flattened for accurate stock removal and reliable measurements

Effect: Good contrast between steels, pronounced ladder rungs with controlled scale — excellent for both subtle and bold etched finishes

Why this billet works for knives

Blade geometry: 290 mm length and 50 mm width give ample stock for full‑size kitchen, hunting, or tactical blades; thickness (6.5 mm) provides good material for profile grinding and beveling while keeping plenty of material for heat treatment.

Steel pairing: 1.2842 and 1.2767 offer responsive hardenability and a clean etched contrast that highlights the ladders pattern after heat treat and etch.

Prep quality: Annealed and flattened surfaces save time during fabrication — you can scribe, cut, and grind with predictable material behavior and accurate dimensions.

Fabrication notes

Heat treat: Follow recommended hardening practice for each steel blend; test a sample to dial in quench and temper for your desired hardness and toughness balance.

Grinding: Use coarser belts initially but protect the pattern with light, consistent passes to avoid excessive heat buildup that can alter surface appearance before final etch.

Etching: Ferric chloride or dilute hydrochloric + peroxide produce strong contrast; test etch times on a scrap to refine the final look.

This billet is ready for knifemakers who want a dependable, attractive ladders Damascus with clean prep work — high carbon content, good contrast, and a flattened, annealed condition that speeds up the build.